Nilo K (For Springs)

A Nickel-Iron-Cobalt, controlled expansion alloy containing 29% Nickel. Its coefficient of expansion (which decreases with rising temperature to the inflection point), matches the expansion rate of borosilicate glasses and alumina ceramics.

Nilo K is also known as Kovar, Dilver, and Pernifer 2918.

Nickel-Iron-Cobalt Base Wire for wire springs, flat springs and wire products

Key Features

- Controlled coefficient of expansion (which decreases with rising temperature to the inflection point).

- Matches the expansion rate of borosilicate glasses and alumina ceramics.

Typical Applications

Glass to metal seals in applications requiring high reliability or resistance to thermal shock, ie. high power transmitting valves.

Approx. Operating Temperature

Chemical Composition

| Element | Ni | Cr | Fe | Mn | C | Cu | Si | Co | Ti | Al | Mo | Mg | Zr |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Min % | 29.00 nominal | – | 53.00 nominal | – | – | – | – | 17.00 nominal | – | – | – | – | – |

| Max % | 29.00 nominal | 0.20 | 53.00 nominal | 0.50 | 0.04 | 0.20 | 0.20 | 17.00 nominal | 0.10 | 0.10 | 0.20 | 0.10 | 0.10 |

Wire Type

- Round

- Flat Wire

- Shaped Wire

- Rope/Strand

Specifications

- ASTM F15

Designations

- W.NR 1.3981

- UNS K94610

- AWS 094

- Related Products

Multi Turn Wave Springs

Multi Turn (Peak-to Peak) Wave springs are formed by stacking successive round edges of wave layers. The peaks correspond to the peaks. Each peak is neatly...

DetailsConstant Force Springs

Constant Force Springs are generally constructed as a pre-stressed flat strip material that is tightly wrapped around a drum or shaft in the center and the hole...

DetailsPower Springs

Power springs are sometimes referred to as clock springs, spiral torsion, flat spiral springs, motor springs or brush springs, they are made by tightly...

DetailsPrecision Stamped Parts & Custom Metal stamping

TSMC is an industry leader in the design and manufacturing of high micro precision parts, or called precision metal stamping, we can formed many different...

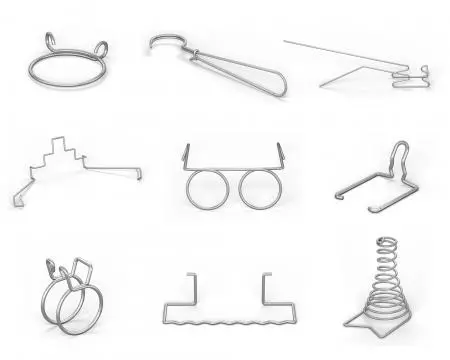

DetailsCNC Wire form Parts

Wire forming is made by the specific configuration of the spool. They can be used in almost any form, and springs of this type are usually custom-made...

DetailsDouble Torsion Springs

Torsion springs are a type of coil or helical spring that react to applied rotational forces, providing torque or using stored rotational energy when the spring...

DetailsExtension Springs

When the tension spring is formed, the spring coils generate a compressive force with each other. When the tensile force acts on the spring, if the force...

DetailsCompression Springs

The cross-section of the spring material used for the compression spring is divided into a circular shape, a rectangular shape, and a multi-strand shape....

DetailsCNC Lathes, Precision Turned Parts

We have wide variety of precision machining equipment's, include CNC lathes and CNC Multi-axis lathe, It has strong and exactly hardness in mechanical...

Details