Precision Stamped Parts & Custom Metal stamping

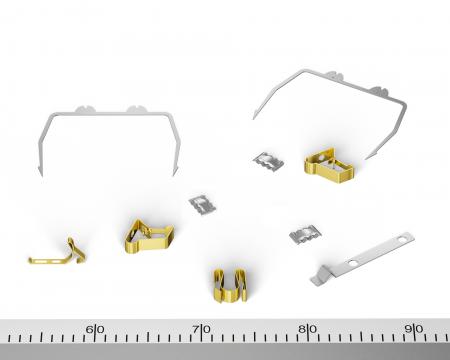

TSMC is an industry leader in the design and manufacturing of high micro precision parts, or called precision metal stamping, we can formed many different shapes from round, rectangular, flat, wedge materials and many custom requirements.

We manufacture parts for many of a broad range of customer applications and offer a vast variety of size and material. Ranging from small parts 0.05mm of width and 0.02mm of thickness, available material in stainless steel and exotic metal alloys, along with our in-house surface finish or assembly work also engineering support from the preliminary design to fabrication.

Backed by our extensive experience, remarkable of engineers and the latest equipment, we have the capabilities to manufacture custom metal shapes and parts for a variety of industries including automotive, aerospace, marine, medical and construction industry and more.

Years of design and manufacturer expertise enable us to meet the needs of the world's most demanding applications as well as custom metal stamping.

Robotic Laser Welding

TSMC has expanded its welding capabilities with the addition of a robotic laser welding. Laser welding is an accurate, clean and flexible option thus can offer a cost-effective and flexible application for achieving high quality weldments. It can reduce the overall weld time, lower distortion and less consumable usage.

Our in-house engineering departments can work with our customers and provide engineered solutions for your parts and assemblies, It can solve many engineering problems that require extremely precise welding.

Custom Design & Engineering Services

As a full service manufacturer, TSMC provides complete fabrication services, our engineering team have capability to supply the custom parts with unique dimensions, features and finishing as well as a complete sub-assemblies to fulfill a production application’s needs. Our experienced engineers can work with our customers’ engineers to recommend manufacturing methods, materials, tolerances, and finishing from idea conception to final product delivery.

One Stop Shop Partner

And as always we are committed to providing quality products and service.

Our service includes:

1. Springs, precision metal parts and plastic injection parts manufacture.

2. Many kind of Shaft parts process with CNC Lathe.

3. Product Surface treatment : PVD, CVD, TELFLON COATING, parylene coating ..etc.

4. Precision laser cutting, laser welding, laser engrave services

5. CNC milling precision processing.

6. Springs, Metal precision and/or Plastic Injection parts combination and assembling.

Application

- At TSMC, our Precision Stamping Parts are widely applied to Solar Equipment, Medical Equipment, Aerospace Equipment, Electronic Components, Cooling Module, LCD Industry, Wireless / Telecommunications Equipment and Others Digital Equipment.

- Related Products

Metal Stampings for solar panel

Since the rise of environmental awareness, the world is turning its focus to cleaner power,...

DetailsHigh precision metal parts & Metal stamping service

At TSMC, we can carry our micro-precision processing for rectangular, round and other shapes...

Details- Related Materials

Corrosion Resistant

Wire for use in corrosive environments such as gases and liquids. Materials which are resistant to chemical attack in acidic, alkaline or complex environments. If...

Electrical and Electronic

Wire used for High Performance electrical and electronic applications (often in high temperatures), selected for their specific electrical and associated...

Strength

Wire for withstanding high loads and / or stresses and those with good strength to weight ratios. In many cases, mechanical properties can be further increased...

Water Resistant

Wire which performs well in aqueous environments. Materials which are resistant to corrosion in subsea or other application areas; where exposure to moisture...

Heat Resistant

Wire for use in high temperatures where high strength, creep and stress rupture resistance, oxidation resistance or a combination of these is required. If...

Controlled / Low Expansion

Wire which has a low or controlled rate of thermal expansion at room temperature, often used in metal to glass sealing or electronic applications. If you have...

Electrical Resistance Wire

Wire used where linear electrical resistance can be achieved through selection of different sizes and shapes. Often used in heating elements or resistors. If...

Hot Cutting and Sealing

Wire used typically for packaging and cutting applications. Materials which have electrical resistance properties which allow them to efficiently reach...

Sub Zero

Wire which has good mechanical properties in low temperature environments, typically materials will be ductile in nature and have good fracture toughness. If...

Specific Applications

Wire that has properties that lend themselves extremely well to being tailored to very specific applications; examples might include medical devices or watch...

Precision Stamped Parts & Custom Metal stamping | Over 31 Years Metal Wave Springs & Retaining Rings Manufacturer | Tech Spring Manufacturing Corp.

Based in Taiwan since 1987, Tech Spring Manufacturing Corp. has been one of the prime precision springs | spring manufacturers. Their main products, including Wave Springs, Retaining Rings and Constant Force Springs, which are designed to meet customers' specified dimensions.

ISO accredited and manufacturing all types of springs, stamping molding and assembly of metal parts to Europe, USA, UK & Australia. We are specialized in the manufacturing, designing and analyzing all kinds of spring, such as wave springs (including of compression wave spring, wave single turn and nested spring), linear expander, retaining rings (including of internal, external, single turn and more turns), constant force spring, power springs (including of general and prestressed types), etc

Tech Spring / TSI / TSMC has been offering customers high-quality precision-made springs, both with advanced technology and 31 years of experience, Tech Spring / TSI / TSMC ensures to meet each customer's demands.