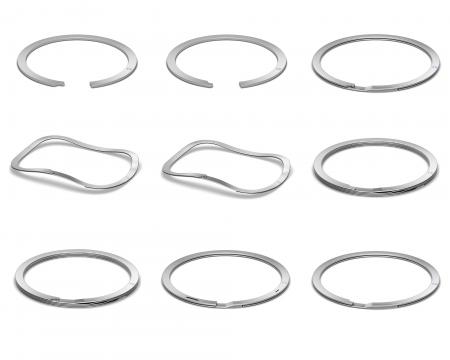

Spiral Retaining Rings

Our Spiral Retaining Rings are manufactured by coiling the ring from flat wire that coiled...

Custom Retaining Rings and Section Selections

TSMC's unique edge-wound manufacturing process produces a variety of ring configurations to meet...

Laminar Seal Rings

Laminar Seal Rings are virtually non-contacting seals with roundness of the ring over 360°...

Constant Section Rings (Snap Rings)

Constant section retaining rings also known as snap rings, feature a uniform, constant section,...

Wave Retaining Rings

Wave Rings are like a constant section ring, but it has an additional compression function....

Self-Locking Rings

Self-Locking Retaining Rings are suitable for applications that have high rotational requirements....

Retaining Rings

TSMC Retaining Rings are available in several types and various sizes, such as Spiral Retaining...