Retaining Rings

Spiral Retaining Rings

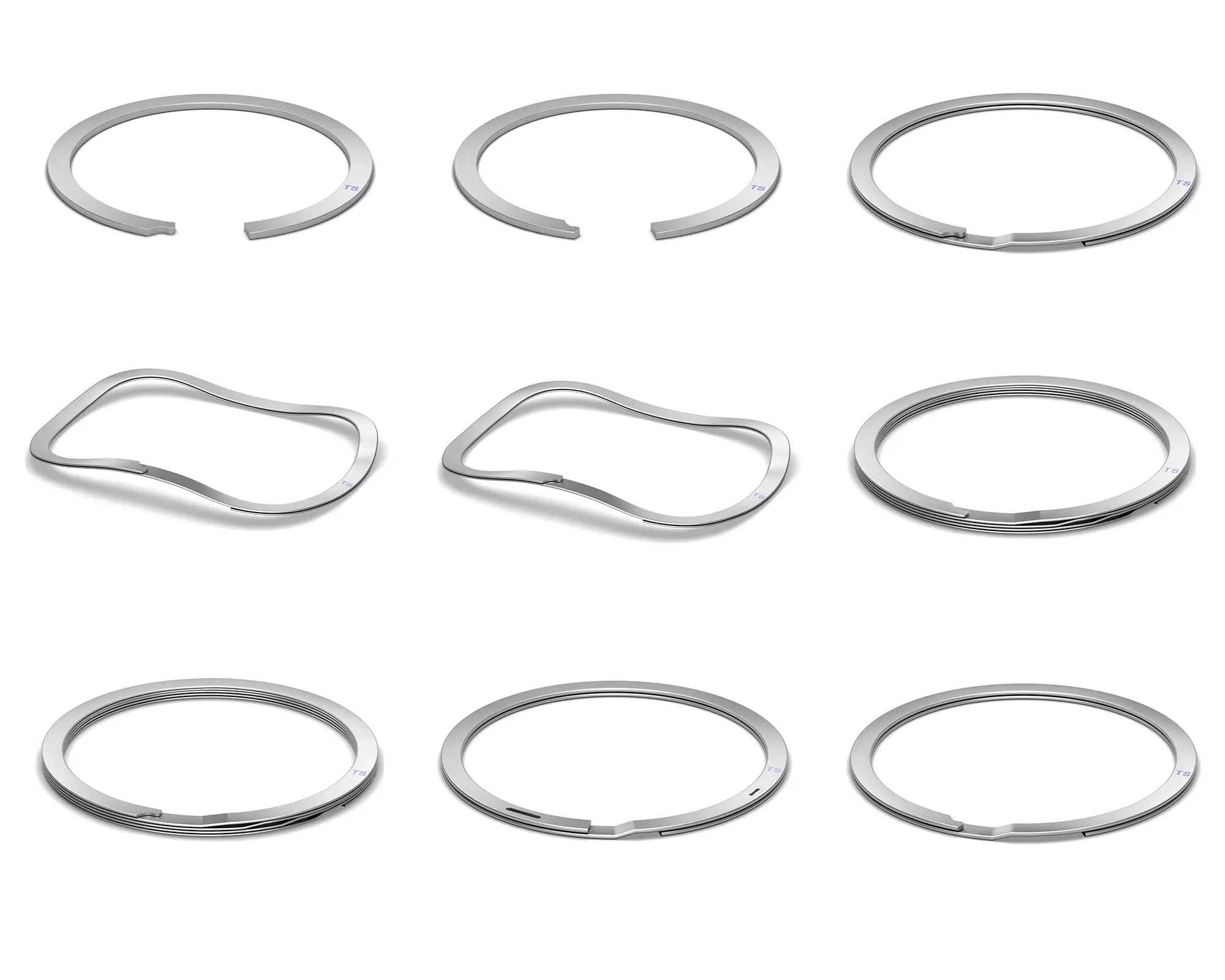

TSMC Retaining Rings are available in several types and various sizes, such as Spiral Retaining Ring, Constant Section Retaining Ring, Wave Rings, Snap Rings, Laminar Seal Rings, Self-Locking Retaining Rings as well as Custom Retaining Ring. It can either be single or multi-turn. The standard material for most retaining rings and Circlips is carbon steel or stainless steel, also many other alloys and finishes are available.

Our Spiral Retaining Rings are manufactured by coiling the ring from flat wire that coiled on edge. The unique coiled-on-edge design provides a gapless ring with 360 of retention and offer space savings in a radial direction since there are No Protruding lugs or ears to interfere with mating components, also No stamped burrs thereby creating a ring with exceptional strength and stability. These retaining rings are economically produced and are ease of assembly that often being more efficient and cost-effective than traditional fasteners or die-stamped circlip.

Spiral Retaining Rings are designed for weight and space-saving applications. This form of retaining rings or circlip often used to fasten assemblies on shafts (EXTERNAL type) or inside housings and bores (INTERNAL type). They are ideal for use in pressure gauge, actuator valves, Gear assembly, lock, Pneumatic clutches, (belt) pulley, connector, hose fitting....etc.

Features

- The use of Winding Shaped Retaining Rings does not have any interference with ears, and the generally stamping retaining ring will interfere with ears.

- A 360° ring that surrounds the support surface to provides more stable support.

- Inner and external diameters are round-edge retaining rings that can mounted on the groove without interference.

- TSMC Retaining Ring’s installation is more convenient and faster, and automatic assembly is adopted.

- TSMC provide ring’s automated assembly design and equipment.

Spiral Retaining Rings

Our Spiral Retaining Rings are manufactured by coiling the ring from flat wire that coiled...

DetailsCustom Retaining Rings and Section Selections

TSMC's unique edge-wound manufacturing process produces a variety of ring configurations to meet...

DetailsLaminar Seal Rings

Laminar Seal Rings are virtually non-contacting seals with roundness of the ring over 360°...

DetailsConstant Section Rings (Snap Rings)

Constant section retaining rings also known as snap rings, feature a uniform, constant section,...

DetailsWave Retaining Rings

Wave Rings are like a constant section ring, but it has an additional compression function....

DetailsSelf-Locking Rings

Self-Locking Retaining Rings are suitable for applications that have high rotational requirements....

DetailsRetaining Rings | ISO 9001 & ISO 14001 Certified Metal Springs Manufacturer Since 1987 | Tech Spring Manufacturing Corp.

Based in Taiwan since 1987, Tech Spring Manufacturing Corp. has been one of the prime precision springs | spring manufacturers. Their main products, including Wave Springs, Retaining Rings and Constant Force Springs, which are designed to meet customers' specified dimensions.

ISO accredited and manufacturing all types of springs, stamping molding and assembly of metal parts to Europe, USA, UK & Australia. We are specialized in the manufacturing, designing and analyzing all kinds of spring, such as wave springs (including of compression wave spring, wave single turn and nested spring), linear expander, retaining rings (including of internal, external, single turn and more turns), constant force spring, power springs (including of general and prestressed types), etc

Tech Spring / TSI / TSMC has been offering customers high-quality precision-made springs, both with advanced technology and 31 years of experience, Tech Spring / TSI / TSMC ensures to meet each customer's demands.