Introduction of special inspection instruments

Since its establishment in 1987, Dayi Spring has been committed to providing customers with the most complete and professional services in the production and production of precision springs or other metals to the manufacturing field. Processes meet the highest quality standards.

Dayi has introduced new inspection equipment to improve product quality.

Our goal is to continuously improve our expertise to provide higher quality, efficiency and service for the overall benefit of our clients.

We use a 1000 times digital microscope to inspect the appearance of the material before the wave spring and shrapnel production and whether there are scratches, cracks, breaks, etc. on the outside of the wave spring and shrapnel after production. All these conditions can be analyzed by digital microscope to ensure the high quality and high yield production of springs and shrapnel. Data analysis through a 1000-fold digital microscope can ensure the production of high-quality products with flawless surfaces.

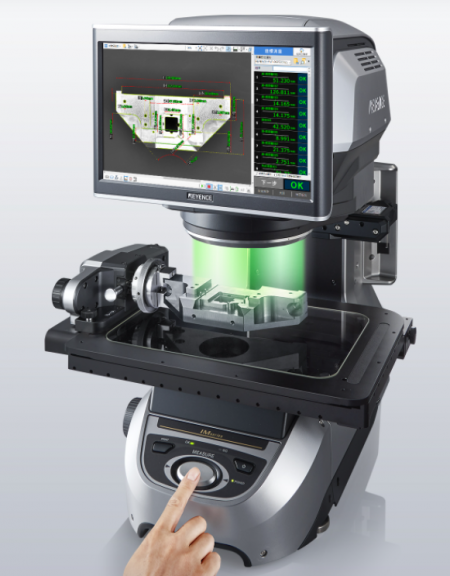

We have a 2D automatic measuring instrument to measure the size of the product, place the product on the instrument and set the parameters, press the measuring button to measure the full size, which greatly reduces the operation time.

OMM automatic measuring instrument is an optical non-contact measurement with ultra-high accuracy. It is used to measure precision springs or products with strict size requirements, such as stamping parts, products with large sizes, extremely small springs, etc. OMM automatic measuring instrument can set automatic measurement, set the measurement parameters for the first measurement, draw circles and lines according to the size of the product, and measure circle to circle, circle to line, and even a little more advanced The concentricity of two circles, the flatness of a plane, the verticality, the true roundness, etc. can be measured and set. After the setting is completed, the first measurement and confirmation are performed. After the confirmation is completed, the file is saved, and then automatic Measurement, product position and fixture position are fixed at the time of setting, ensuring accurate measurement every time. According to the size of the product, draw a circle or even advance a little to the concentricity, flatness, etc. of two circles