Inconel 718 (For Springs)

A Nickel-Chromium alloy being precipitation hardenable and having high creep-rupture strength at high temperatures to about 700°C (1290°F). It has higher strength than Inconel X-750 and better mechanical properties at lower temperatures than Nimonic 90 and Inconel X-750. It can be used for any TSMC spring product such as wave springs, retaining rings and compression springs.

Inconel 718 is also known as Nicrofer 5219, Superimphy 718, Haynes 718, Pyromet 718, Supermet 718. and Udimet 718.

Nickel Base Wire for wire springs, flat springs and wire products

Key Features

- Good creep rupture strength at high temperatures

- Higher strength than Inconel X-750

- Better mechanical properties at lower temperatures than Nimonic 90 & Inconel X-750

- Age hardenable

- High temperature dynamic applications

Typical Applications

Gas Turbines

Rocket Motors

Space Craft

Nuclear Reactors

Pumps

Approx. Operating Temperature

Chemical Composition

| Element | Ni | Cr | Fe | Mn | C | Cu | Si | S | P | Co | Nb/Cb | Ti | Ta | Al | Mo | B | Pb | Bi | Se |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Min % | 50.00 | 17.00 | bal | – | – | – | – | – | – | – | 4.75 | 0.65 | – | 0.20 | 2.80 | – | – | – | – |

| Max % | 55.00 | 21.00 | bal | 0.35 | 0.08 | 0.30 | 0.35 | 0.015 | 0.015 | 1.00 | 5.50 | 1.15 | 0.05 | 0.80 | 3.30 | 0.006 | 0.0005 | 0.00003 | 0.0003 |

Wire Type

- Round

- Flat Wire

- Shaped Wire

- Rope/Strand

Specifications

- AMS 5662

- AMS 5663

- AMS 5832

- AMS 5962

- ASTM B637

- GE B5OTF14/15

- GE B14H89

- ISO 15156-3 (NACE MR 0175)

Designations

- W.NR 2.4668

- UNS N07718

- AWS 013

- Related Products

Multi Turn Wave Springs

Multi Turn (Peak-to Peak) Wave springs are formed by stacking successive round edges of wave layers. The peaks correspond to the peaks. Each peak is neatly...

DetailsConstant Force Springs

Constant Force Springs are generally constructed as a pre-stressed flat strip material that is tightly wrapped around a drum or shaft in the center and the hole...

DetailsPower Springs

Power springs are sometimes referred to as clock springs, spiral torsion, flat spiral springs, motor springs or brush springs, they are made by tightly...

DetailsPrecision Stamped Parts & Custom Metal stamping

TSMC is an industry leader in the design and manufacturing of high micro precision parts, or called precision metal stamping, we can formed many different...

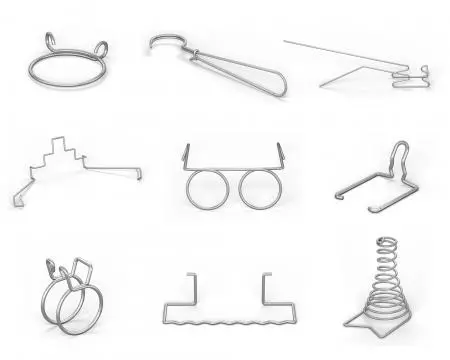

DetailsCNC Wire form Parts

Wire forming is made by the specific configuration of the spool. They can be used in almost any form, and springs of this type are usually custom-made...

DetailsDouble Torsion Springs

Torsion springs are a type of coil or helical spring that react to applied rotational forces, providing torque or using stored rotational energy when the spring...

DetailsExtension Springs

When the tension spring is formed, the spring coils generate a compressive force with each other. When the tensile force acts on the spring, if the force...

DetailsCompression Springs

The cross-section of the spring material used for the compression spring is divided into a circular shape, a rectangular shape, and a multi-strand shape....

DetailsCNC Lathes, Precision Turned Parts

We have wide variety of precision machining equipment's, include CNC lathes and CNC Multi-axis lathe, It has strong and exactly hardness in mechanical...

Details