Compression Springs

The cross-section of the spring material used for the compression spring is divided into a circular shape, a rectangular shape, and a multi-strand shape. In recent years, in order to improve the utilization of the spring material, a pipe material is also used. In order to improve the fatigue strength, the cross section of the flat material is also gradually expanded.

The compression spring has a wide application, and the spring has sufficient clearance between each turn. The gap can be shortened after compression, and the original length is restored when the pressure disappears. In order to increase the contact area of the spring, the ends of the spring are often flattened.

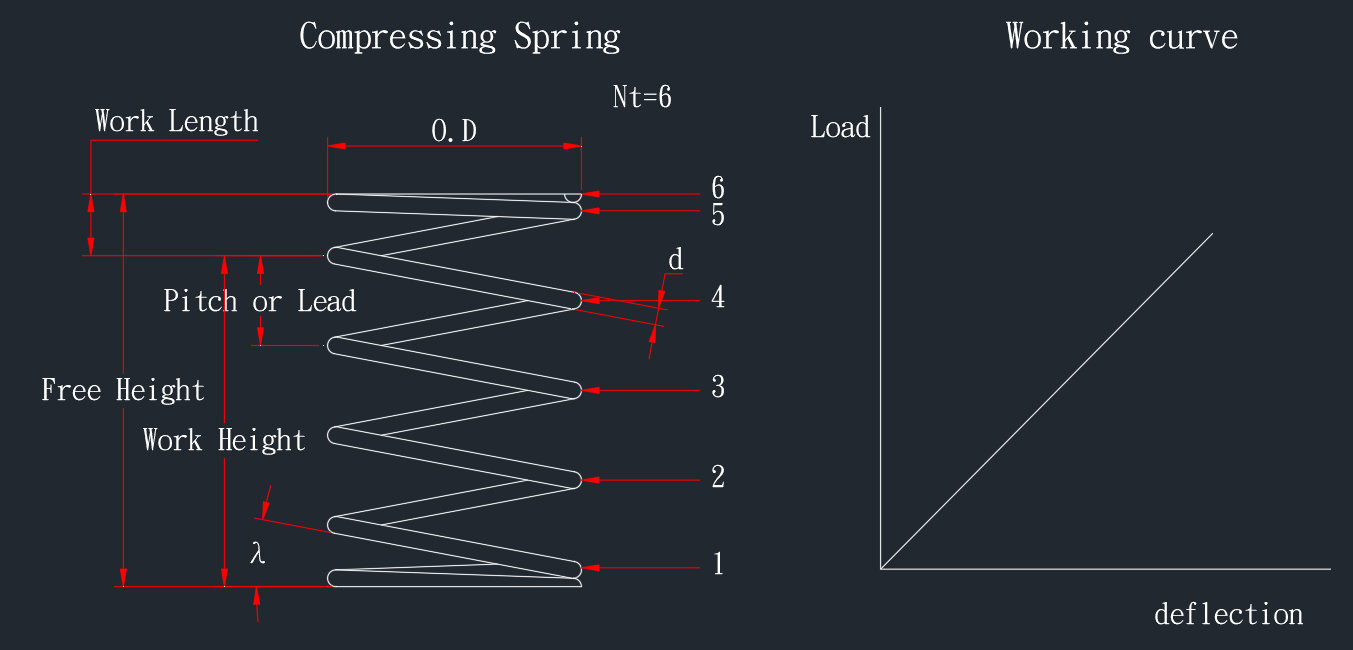

The compression spring is generally of equal intercept. In special cases, there is also an equal intercept. When the compression spring is equal to the intercept, its characteristic line is linear. When the intercept is not equal, the characteristic line is nonlinear.

TSMC produces pressure springs of various sizes and shapes, such as straight barrels, cones, barrels, etc. If you have special needs for compression springs, our experienced engineers will design for you (Including load and service life and other characteristics), manufacturing products that meet your company's needs.

Gallerys

- Compression-Springs-1

- Compression-Springs-2

- Compression-Springs-3

- Compression-Springs-4

- Compression-Springs-5

- Compression-Springs-6

- Compression-Springs-7

Engineering Design

Custom products are a specialty of TSMC (Tech Spring Manufacturing Corp.), as a full service precision manufacturing company, our experienced engineers have extensive knowledge of custom parts, they are always available to assist you to conduct a comprehensive functional analysis of development and gives a feasible solution through our own formula from the preliminary design phase to fabrication that meets your application needs.

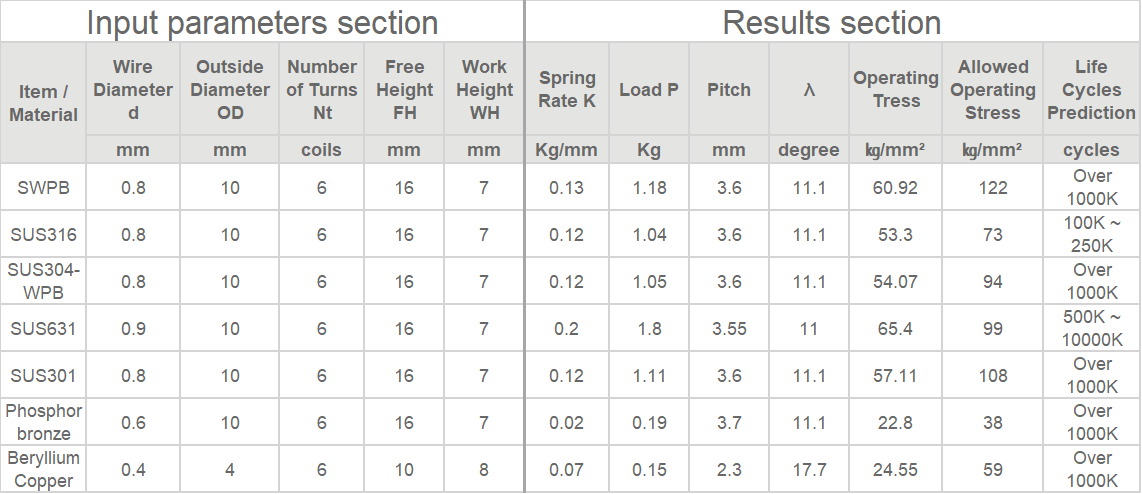

There are four critical factors when considering a Compression Springs design such as Bore/ shaft (ID/OD), Load, Working height at which the load is applied and Material desired, as well as the other input parameters that contain the wire thickness, wire radial wall, active number of turns, work height, load at work height ... The input data as shown on the left table. And calculation results with spring rate (stiffness), working load (±10%), outer diameter at solid height, Working curve and Life cycles prediction where found in the down table.

Whether you need a standard or custom Compression Springs, please send us your application requirement, our experts will hand-select or commend the best solution for your specific needs.

- Related Materials

Corrosion Resistant

Wire for use in corrosive environments such as gases and liquids. Materials which are resistant to chemical attack in acidic, alkaline or complex environments. If...

Electrical and Electronic

Wire used for High Performance electrical and electronic applications (often in high temperatures), selected for their specific electrical and associated...

Strength

Wire for withstanding high loads and / or stresses and those with good strength to weight ratios. In many cases, mechanical properties can be further increased...

Water Resistant

Wire which performs well in aqueous environments. Materials which are resistant to corrosion in subsea or other application areas; where exposure to moisture...

Heat Resistant

Wire for use in high temperatures where high strength, creep and stress rupture resistance, oxidation resistance or a combination of these is required. If...

Controlled / Low Expansion

Wire which has a low or controlled rate of thermal expansion at room temperature, often used in metal to glass sealing or electronic applications. If you have...

Electrical Resistance Wire

Wire used where linear electrical resistance can be achieved through selection of different sizes and shapes. Often used in heating elements or resistors. If...

Hot Cutting and Sealing

Wire used typically for packaging and cutting applications. Materials which have electrical resistance properties which allow them to efficiently reach...

Sub Zero

Wire which has good mechanical properties in low temperature environments, typically materials will be ductile in nature and have good fracture toughness. If...

Specific Applications

Wire that has properties that lend themselves extremely well to being tailored to very specific applications; examples might include medical devices or watch...

Compression Springs | Over 31 Years Metal Wave Springs & Retaining Rings Manufacturer | Tech Spring Manufacturing Corp.

Based in Taiwan since 1987, Tech Spring Manufacturing Corp. has been one of the prime precision springs | spring manufacturers. Their main products, including Wave Springs, Retaining Rings and Constant Force Springs, which are designed to meet customers' specified dimensions.

ISO accredited and manufacturing all types of springs, stamping molding and assembly of metal parts to Europe, USA, UK & Australia. We are specialized in the manufacturing, designing and analyzing all kinds of spring, such as wave springs (including of compression wave spring, wave single turn and nested spring), linear expander, retaining rings (including of internal, external, single turn and more turns), constant force spring, power springs (including of general and prestressed types), etc

Tech Spring / TSI / TSMC has been offering customers high-quality precision-made springs, both with advanced technology and 31 years of experience, Tech Spring / TSI / TSMC ensures to meet each customer's demands.